1、整机按要求设计制造,高标准、高可靠性、安全性。

2.本机采用PLC单独控制,彩色触摸屏显示,参数设置和显示直观。

3、所有电器、电子、气动元件均采用国际名牌产品。

4.选用优质、高标准的材料和配件。

5、主传动齿轮全部采用特殊进口材料,磨削精度高,经久耐用,齿轮润滑采用油泵喷油系统。

6.自动归零。

7.可以存储不同的订单,加快订单操作。

8、无键领、长效、印刷精度高。

1, the machine is designed and manufactured according to the requirements, with high standards, high reliability and safety.

2. This machine is controlled by PLC alone, color touch screen display, parameter setting and display intuitive.

3. All electrical, electronic and pneumatic components adopt international famous brand products.

4. Select high quality and high standard materials and accessories.

5. the main drive gear all adopt special imported materials, grinding precision is high, durable, gear lubrication oil pump injection system.

6. Automatically reset to zero.

7. Different orders can be stored to speed up order operation.

8. keyless collar, long effect, high printi

前缘部

1.先进的前送料系统,操作简单,精度高。

2.7.5kw高压离心风机,可根据纸板翘曲程度调节风量,确保进纸板顺畅。

3.挡板位置由丝杆驱动电动调节,或挡板气动薄膜装置。

4.每张纸,可以根据需要选择每张大尺寸的纸和纸板也可以加工。

5、7寸真彩触摸屏安装,200组可预置订单、查询订单、调零。订单录入、机器同步调零、相位自动/手动调整、机器参数管理、升降版分配手动/自动控制,自动显示生产数量和生产速度并设定生产数量。

6.带槽部设有联锁控制开关,停止、停止送纸或复位送纸,正反转,各单元相分,人性化操作。

7.带槽部设有联锁控制开关,停止、停止送纸或复位送纸,正反转,各单元相分,人性化操作。

8.用毛刷擦拭除尘装置,并配有强力负压吸风机,清除纸板表面的灰尘、纸屑等杂物,提高印刷质量。

1. Advanced front feeding system, simple operation, high precision.

2.7.5kw high pressure centrifugal fan can adjust the air volume according to the degree of cardboard warping to ensure smooth feeding into the cardboard.

3. The baffle position is electrically adjusted by the lead screw drive, or the baffle pneumatic film device.

4. Each paper can be selected according to the need of each large size of paper and cardboard can also be processed.

5, 7 inch true color touch screen installation, 200 sets can be preset order, order query, zero. Order entry, machine synchronous zero adjustment, automatic/manual phase adjustment, machine parameter management, manual/automatic control of lifting plate distribution, automatic display of production quantity and production speed and set production quantity.

6. Interlocking control switch is arranged in the groove part, which can stop, stop or reset the paper feeding, reverse and reverse, each unit is divided, user-friendly operation. 7. Interlocking control switch is arranged in the groove part, which can stop, stop or reset the paper feeding, reverse and reverse, each unit is divided, user-friendly operation.

8. Wipe the dust removal device with a brush and equipped with a strong negative pressure suction fan to remove dust, paper scraps and other sundries on the surface of the cardboard and improve the printing quality.

印刷部

1.优质钢材制作,表面研磨,镀硬铬。静平衡调节,运行平稳,适应高速运转。

2.轧辊水平方向和圆周方向有其公线,便于版型。

3.棘轮固定卷轴版,左右锁紧装置,使挂版对位更快速准确。

4.安装脚踏开关控制盘滚筒正反,方便换版。

5.间隙调节自锁蜗轮箱精度高,并配有三阀杆盘手柄,方便快捷。调整范围 0 到 11 毫米。

6.精细的优质无缝钢管加工,钢管表面研磨镀硬铬,动平衡校正。

7.印刷阶段PLC触摸屏控制和电动数字360°调节(运动和停止均可调节)。

8、自动调零装置,确保机组有统一的调整基准,试运行一次即可调整正确位置,减少纸板浪费。

9.压力式自动升降齿轮辊,并有空转装置,送料网纹辊与版材接触时下降,停止送料网纹辊自动上升和版材分离,以保护版材;不要按自动空转,防止墨水干涸

1. High quality steel production, surface grinding, hard chrome plating. Static balance adjustment, stable operation, suitable for high speed operation.

2. The horizontal and circular direction of the roll has its common line, which is convenient for the version.

3. Ratchet fixed scroll plate, left and right locking device, so that the plate alignment faster and more accurate.

4. Install foot switch to control the cylinder positive and negative, convenient for changing version.

5. Clearance adjustment self-locking worm gear box high precision, and equipped with three valve stem disc handle, convenient and fast. Adjustment range 0 to 11 mm.

6. Fine quality seamless steel pipe processing, steel pipe surface grinding hard chrome plating, dynamic balance correction.

7. PLC touch screen control and electric digital 360° adjustment (movement and stop can be adjusted) in the printing stage.

8, automatic zero adjustment device, ensure that the unit has a unified adjustment benchmark, test run can adjust the correct position, reduce cardboard waste.

2. Pressure type automatic lifting gear roller, and idling device, feeding roller and plate material contact down, stop feeding roller automatically rising and plate material separation, to protect plate material; Do not press automatic idling to prevent the ink from drying up

开槽部

1. 电控刀轴调整,垂直及高尺寸箱体。

2.间隙调整采用高精度自锁蜗轮箱,配备三阀杆盘手柄,方便快捷。调整范围为 0-11 毫米。

3.行星齿轮结构,使用寿命长。

4.开槽相位PLC触摸屏控制和电动数字360°调节(运动和停止均可调节)。零相装置。

5、双槽、单轴、高箱内齿调节电气结构,使润滑油不易污染纸箱。并有高度的调节箱防撞保护,不损坏机器。

6.采用独特的弹片式除尘装置,操作方便。

1.Electric control tool shaft adjustment, vertical and high size box.

2. Clearance adjustment adopts high-precision self-locking worm gear box, equipped with three valve stem disc handle, convenient and quick. The adjustment range is 0-11 mm.

3. Planetary gear structure, long service life.

4. Slotting phase PLC touch screen control and electric digital 360° adjustment (movement and stop can be adjusted). Zero phase device.

5, double groove, single axis, high box teeth adjust the electrical structure, so that the lubricating oil is not easy to pollute the carton. And the height of the adjusting box anti-collision protection, no damage to the machine.

6. Adopt unique shrapnel type dust removal device, easy to operate.

模切部

1.软滚切机构,提高板坯重复使用率。

2.线速度自动补偿,确保每批纸箱模切尺寸准确。

3.CAM型软辊横向移动40mm,MATS磨损均匀,提高脚垫利用率降低成本。模切相采用电动4、

4. 360°数字调节(运动和停止均可调节)。

5.进纸轴,抛光,镀硬铬,配备四轮进纸。

6、送料辊齿轮无间隙调节机构,调整不影响齿轮,保证传动精度。

7.间隙调节自锁蜗轮箱,精度高,方便快捷。调整范围 0 到 11 毫米

1.Soft rolling cutting mechanism to improve the repeated utilization rate of slab.

2. The linear speed is automatically compensated to ensure the accuracy of die-cutting size of each carton.

3. Cam-type soft roll moves 40mm laterally, MATS wear evenly, improve the utilization rate of footpads and reduce costs. Die-cutting phase using electric

4. 360° digital adjustment (movement and stop can be adjusted).

5. Feed shaft, polished, hard chrome plated, equipped with four wheel feed.

6, feeding roller gear clearance adjustment mechanism, adjustment does not affect the gear, ensure transmission accuracy.

7. Clearance adjustment self-locking worm gear box, high precision, convenient and fast. Adjustment range 0 to 11 mm.

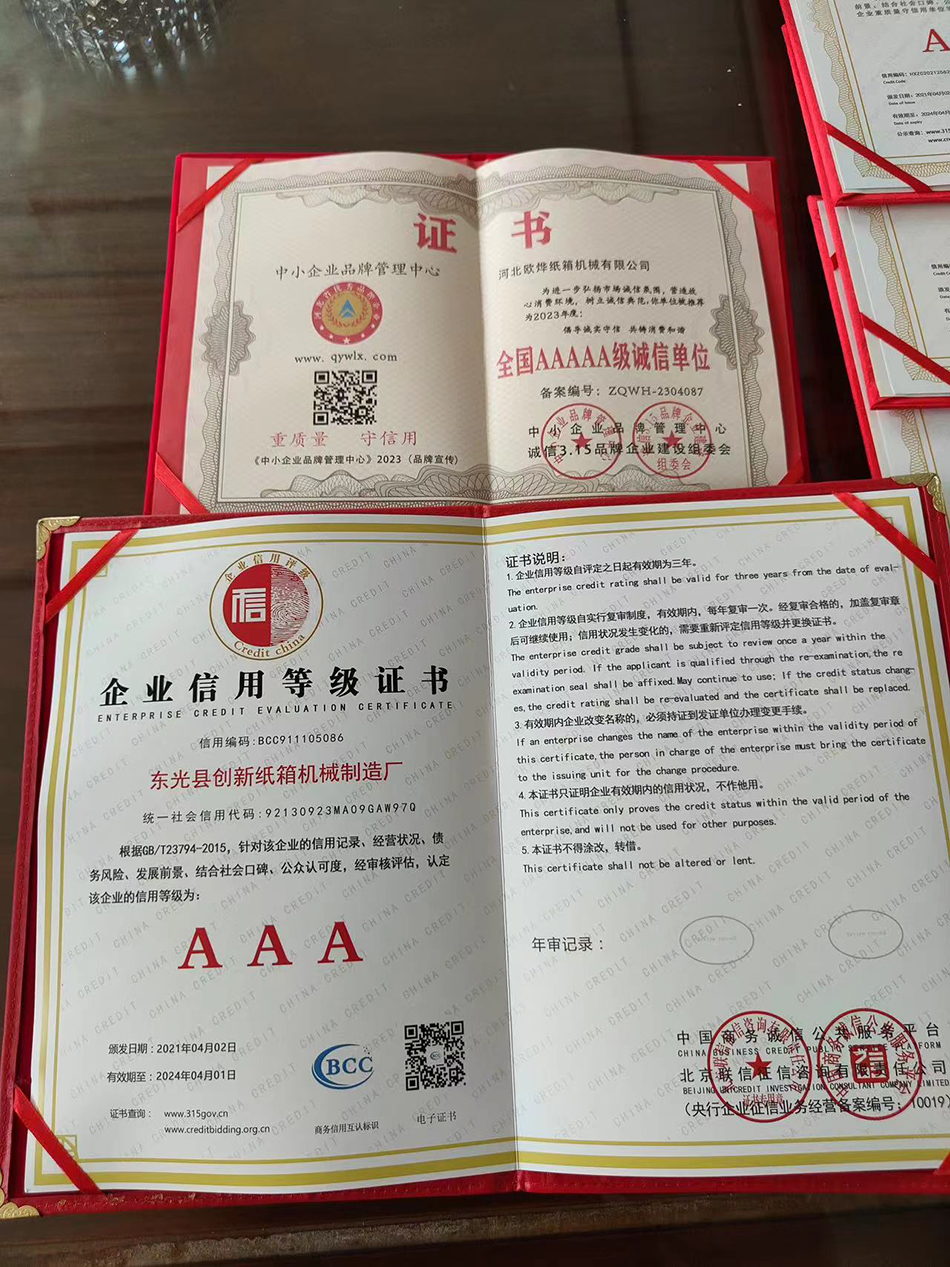

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

stacker-machine.180.3-1.jpg)

stacker-machine.180.3-2.jpg)

stacker-machine.180.3-3.jpg)

stacker-machine.180.3-4.jpg)