Full auto stitching high speed corrugated carton machine

Overview

Essential details

Warranty:1 Year

Type:Other

Applicable Industries:Hotels, Garment Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Printing Shops, Food & Beverage Shops, Other, Advertising Company

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Condition:New

Application:Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type:Cartons, case

Packaging Material:Paper

Automatic Grade:Automatic

Driven Type:Mechanical

Voltage:380V 3P 50HZ

Power:20kw

Place of Origin:HenBei, China

Brand Name:CHUANG XIN

Weight:7000 KG

Key Selling Points:Competitive Price/Easy to Operate/High efficiency

Product name:Stitching And Folding Gluing Carton Box Folder Gluer Machine

★French Schneider original imported dual servo drive, accuracy, mechanical transmission part reduction, can effectively reduce the failure rate of machinery.

★Weilan touch screen operation, parameters (nail distance, nail number, nail type, rear baffle) convenient and fast change. ★The whole control system adopts Japanese Omron PLC control system. ★Rear electric baffle, driven by stepper motor, accurate size, more convenient to change size. ★The full contactor in the control cabinet adopts Mitsubishi brand. ★The optoelectronic and proximity switches use schneider brand. ★Bottom die, blade made of Japan tungsten steel (wear - resistant). ★The whole group of nails are all made of special steel, computer gong precision machining. ★Can suit the different requirements of different customers. ★It takes only one minute to change the size of the carton and adjust the stitching distance of the carton, greatly saving time and convenient operation. ★The front feed unit counts automatically, and the feed table is equipped with photoelectric induction device, which rises automatically when feeding. ★The back section has an automatic counting function, and the finished sheets can be sent to the end of the feeding machine in stacks according to the set number (1-99), which is convenient for packing and strapping. ★Mechanical speed: 450 nails/min. ★Nail distance :200-260mm adjustable.Electric adjustment of press rubber wheel gap. ★Protection function of electrical isolating transformer of whole machine; ★Front and back baffle configuration, can order carton and small cardboard box, color box. ★Japanese special die steel forging for head punch body.

Size Information

|

largest size(A+B)X2 |

3600mm |

Minimum length A |

250mm |

|

smallest size(A+B)X2 |

740mm |

Maximum height D |

2000mm |

|

largest size(C+D+C) |

3000mm |

Minimum height D |

150mm |

|

smallest size(C+D+C) |

250mm |

Maximum nail tongue width E |

40mm

|

|

Minimum shake cap C |

50mm

|

Maximum feed height |

900mm |

|

Maximum shake cap C |

560mm |

Mechanical width |

2850mm |

|

Maximum width B |

760mm |

Mechanical weight (T) |

1.5 |

|

Minimum width B |

120mm |

Mechanical speed (nails/min) |

450 |

|

Maximum length A |

1120mm |

The number of order |

1.99 |

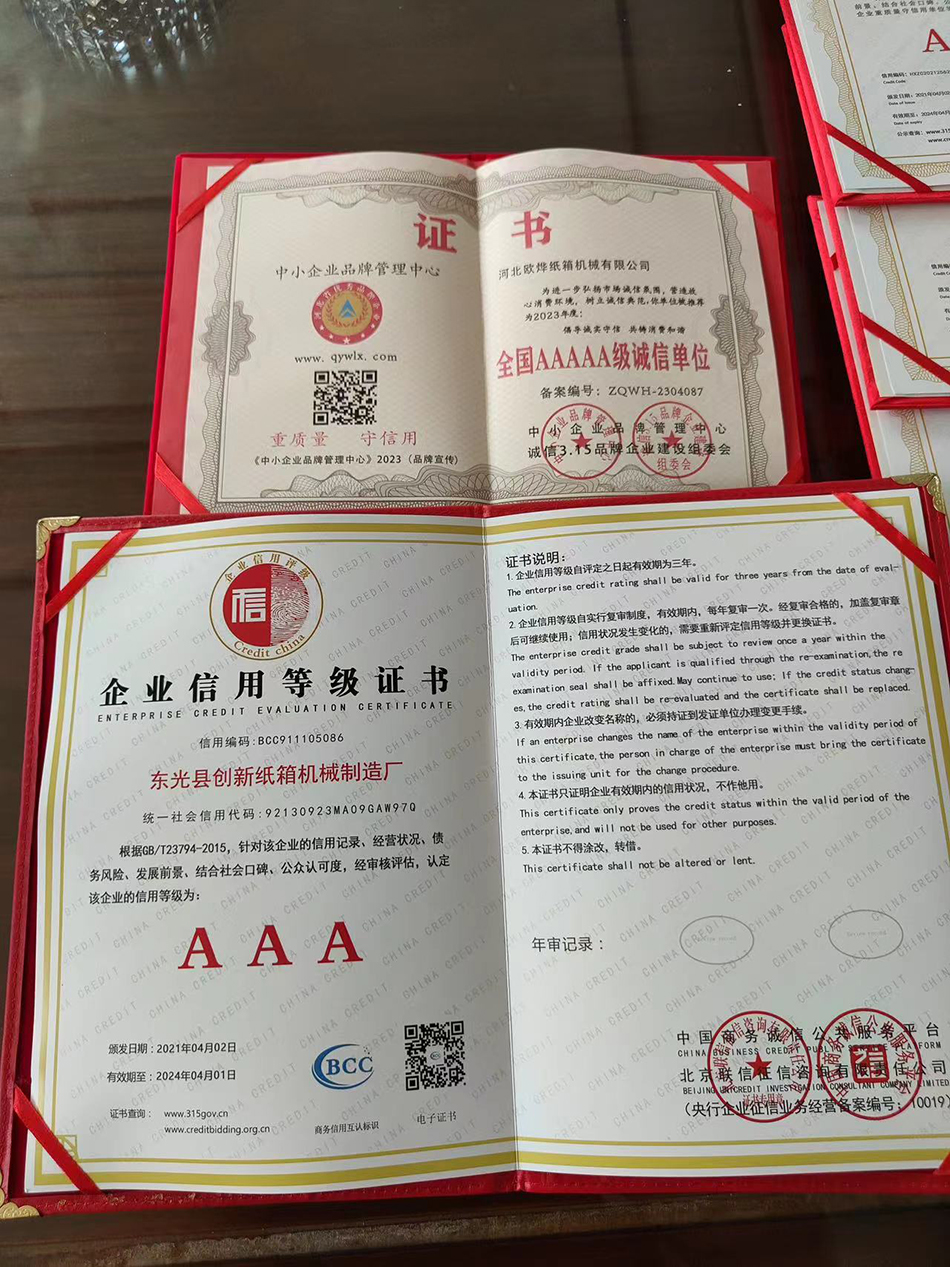

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory