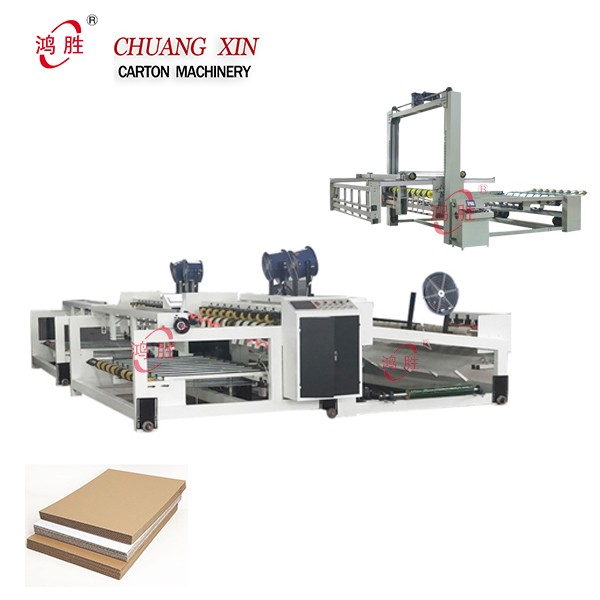

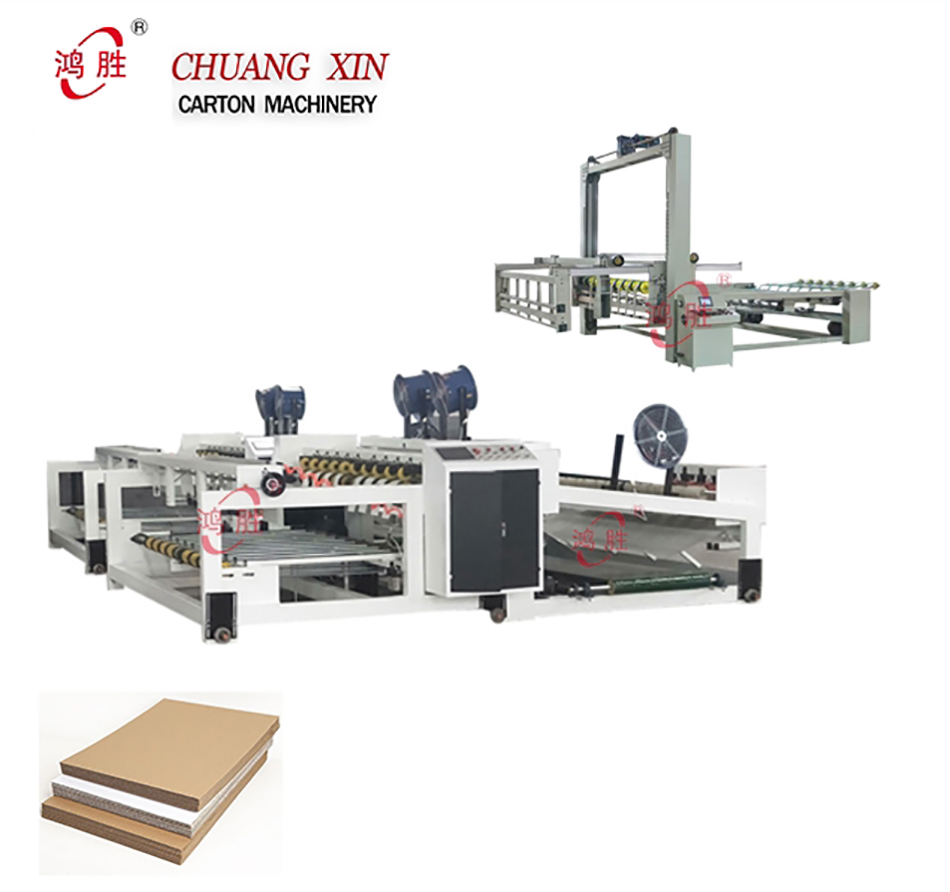

Corrugated Paper Waste Vibrate Stripping Machine/carton Box Stripper

Product Description

1) The paper can then manually adjust automatically.

2) splicing speed and feed speed is synchronization, then the paper speed can be adjusted independently

3) The stack height of 1700 mm

4) bed units lifting strength chain drive.

5) The splicing platform equipped with anti-fall device to ensure operator safety.

6) take action paper hanging pressure plates stacked in cardboard to a certain height, then lift up out of cardboard board automatically.

This machine is a auxiliary machine for the corrugated carton printer slotter die cutter machines. It's function is to convey and collect the finished flat cartons. Suitable for 3/5/7 layer corrugate cardboard( as well as E flute paper board.)

Vibrator Cleaner Part:

1. All motors of thecleaner machineare individually controlled by independent buttons, which can be operated independently according to production requirements. The speed of the motor can be adjusted. Equipped with an emergency stop button device to ensure the safety of mis-operation.

2. The paper receiving sectionis equipped with pressure strips, so that the cardboard can smoothly and smoothly enter the main drive shaft of the waste removal. The paper receiving platform can be lifted up and down toadapt to the height of different die cutting machines.

3. The vibration belt adopts imported cylindrical high elastic belt, which is durable to use, and it is not easy to damage the cardboard under high-speed shaking; the belt shaft is a cylindrical belt shaft with a semi-circular groove, and the position of the belt can be adjusted at will, so as to adapt to all kinds of special-shaped cardboard. Production demand.

4 The main waste removal mechanism is composed of a double oscillating waste removal mechanical structure, each oscillating waste removal structure is driven by an independent motor, and a better waste removal effect can be achieved through different degrees of vibration frequency; the rear end is equipped with a brush setting to make The shaken cardboard scraps are easier to fall, and the best effect of waste removal is achieved; the sloped flat plates on both sides under the waste removal section and the waste paper guide plate at the rear end of the waste removal section can be easily matched with waste paper The output belt completely outputs the waste paper

5. The main drive shaft is driven by an independent motor. It consists of four full shafts with concave wheels, two on the top and two on the top and two on the top. There is a slot for every ten centimeters on the wheel. It is convenient to adjust the belt according to the actual cardboard size to ensure the smooth passage of the special-shaped carton. And to avoid damage to the cardboard; the shaking shaft transmission is controlled by an independent motor, which can be controlled separately, and the speed is convenient to adjust to ensure the shaking stroke; the shaking shaft adopts two-axis operation, and each axis is composed of four shaking points to accelerate the shaking frequency and increase Jitter effect.

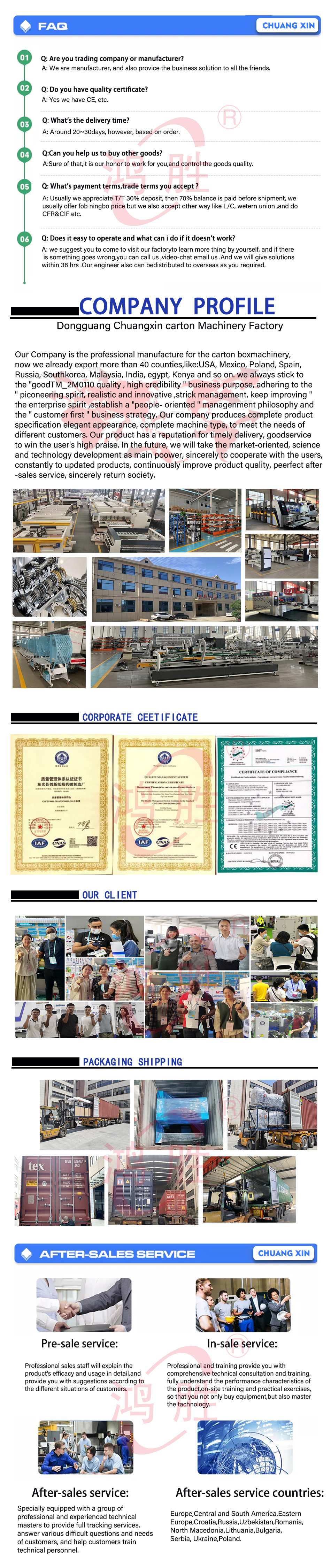

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory