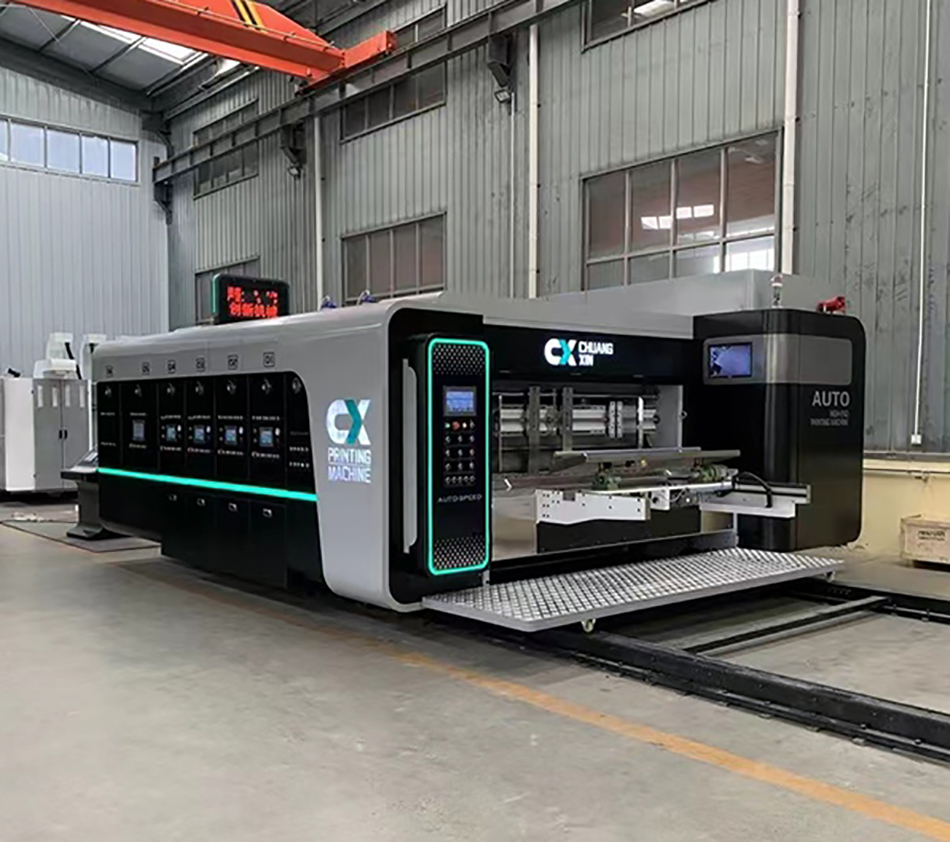

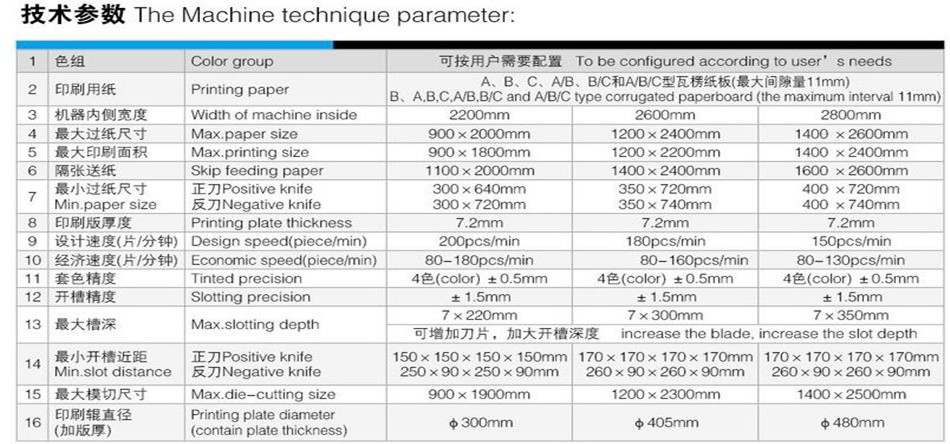

Flexo Printing Paperboard Carton Rotory DIe-Cutting Automatic Full High Definition Machines

High Speed Automatic Lead Edge Flexo Printer Slotter Diecutter Machine CE Certified,300Pcs Per Min

I General Features

00001.

Stable: The lead feeder, servo phase, vacuum adsorption, many rows dislocation arrangement design, favors the cardboard stable transmission. Reinforced frame positioning device, gear direct rigid connection in the wallboard, imported gear from Taiwan and bearing from japan with high speed and long-term stability, with integral anilox roller lift version to keep promotion assure printing, the whole machine adopts the French Schneider electric, host, fan, PLC, touch screen use GERMAN SIEMENS.

Precision: Rubber roller surface with double glue technology, low pressure transmission from the impact of the pneumatic pressure, can control the whole vacuum adsorption, more with a word dislocation encryption round ceramic array, cardboard more adsorption, without beating, the overall precision of the anilox roller transmission device, full speed to reduce anilox roller beating, with servo phase adjustment increase anilox roller printing quality, down adjustment pressure structure of the die cutting roller keep paperboard line transmission precision guarantee.

Efficiency: Patent type feeding width automatic adjustment device and printing locking device with screw. With 4.0 engineering design of industrialization, both hardware and software are charged with the author’s high efficiency tools. Feeding – dust removing – printing – pre drying- coating- drying-slotting- die cutting-gluer line- case maker

Service: Based on the industry’s first use of PDM design file management system, complete technical support files, regardless of the long time can still be credible commitment to customers, continuous and efficient after-service for the customer support.

This machine also with long-range control with internet. We can monitoring the machine and do service in China office.

II Feeding Department

Servo moter independent drive, with Japan's Shimpo feeding speed reducer, high precision.

The servo motor drives the roller type front feed.

The installation of antistatic device.

Eliminate dust, electrostatic effects on dust particles and not easy to brush.

III Dust Removal Department

The paper feeding unit after the special configuration of the dust removal ynt is a reliable guarantee for high precision printing.

The eight groups brush to dust on the surface of the brush board.

The two group of stong negative pressure type vaccum blower, dust brush has completely removed.

The sticky roller can clay the rest of the tiny particle on it's surface, making field effect of printing whithout any defects, effectively reduce the downtime wipe wersion number.

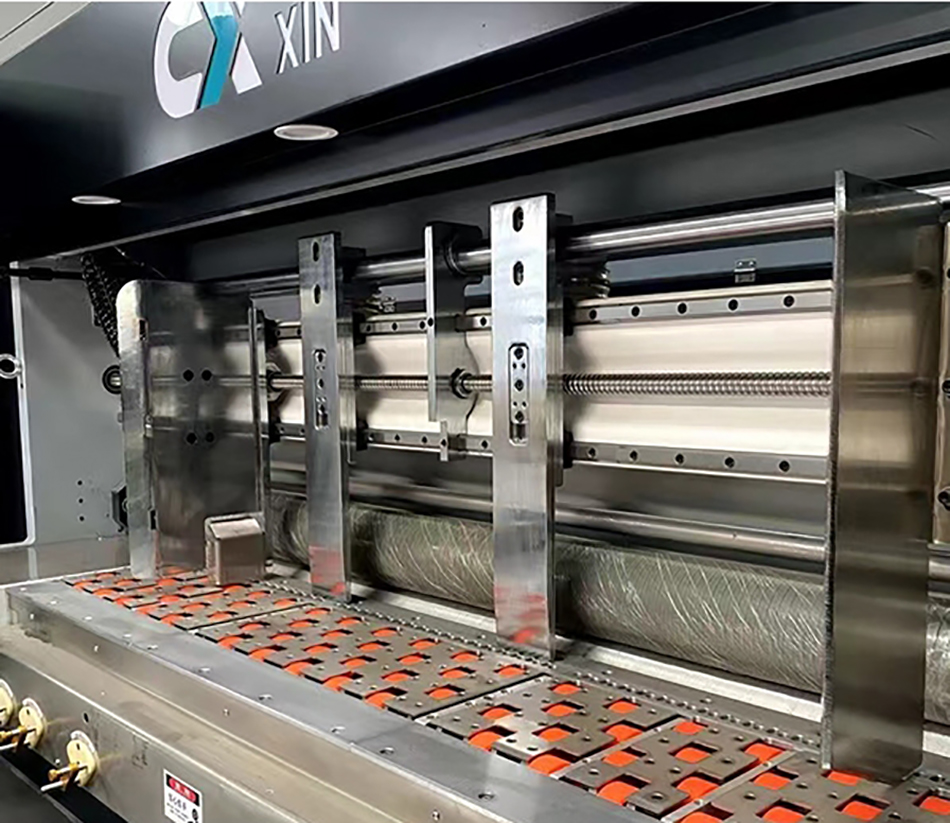

IV Slotting Unit

Single shaft five blades slotting ,an internal gear adjusts the height of the carton box and prevents the lubricating oil from spilling or leaking onto the cardboard

The first pre-creasing,the cardboard not be damaged after prepressing.

Upper creasing roll covered by anvil ring,so cardboard is not damaged easily.

Slotting bosses move along liner lead rails and are driven by lead screws for flexible and precise movement.

Upper boss and lower boss are coupled to keep the two knives aligned while moving,which is helpful to prolong service life.

Slotting register and height of carton box are digital controlled by motor and PLC.

Transversal movement of the pre-creasing rolls,and slotting bosses’ are digital controlled by motor and PLC Motorized controls of the slotting bosses caliber.

00001.

A protective device prevents the slotting knife from crashing when the height of the carton box is adjusted.

Flexible angle cutting knife can cut 3 or 5 or 7 ply cardboard with no adjustment,easy to operate.

V Die Cutting Unit

With separate servo motor.

Side to side oscillation of anvil drum(45mm)

The die drum’s transverse movement can prolong the service life ofanvil cover.

Die-cutting register is digitally controlled by motor and PLC

The die-cut cylinder lateral register is digitally controlled by motor and PLC,rang about±10mm

Motorized caliper adjustment between anvil roll and die drum.

Auto speed compensation system controlled by the independent motor can achieve the superb die accuracy.

Anvil rubber roller speed compensation adopted independent motor for driving to control the rubber roller speed,the compensation scope is ±3mm.

Anvil trimmer to keep surface of the anvil covers flat and smooth.

Anvil cover is Depride made from Germany

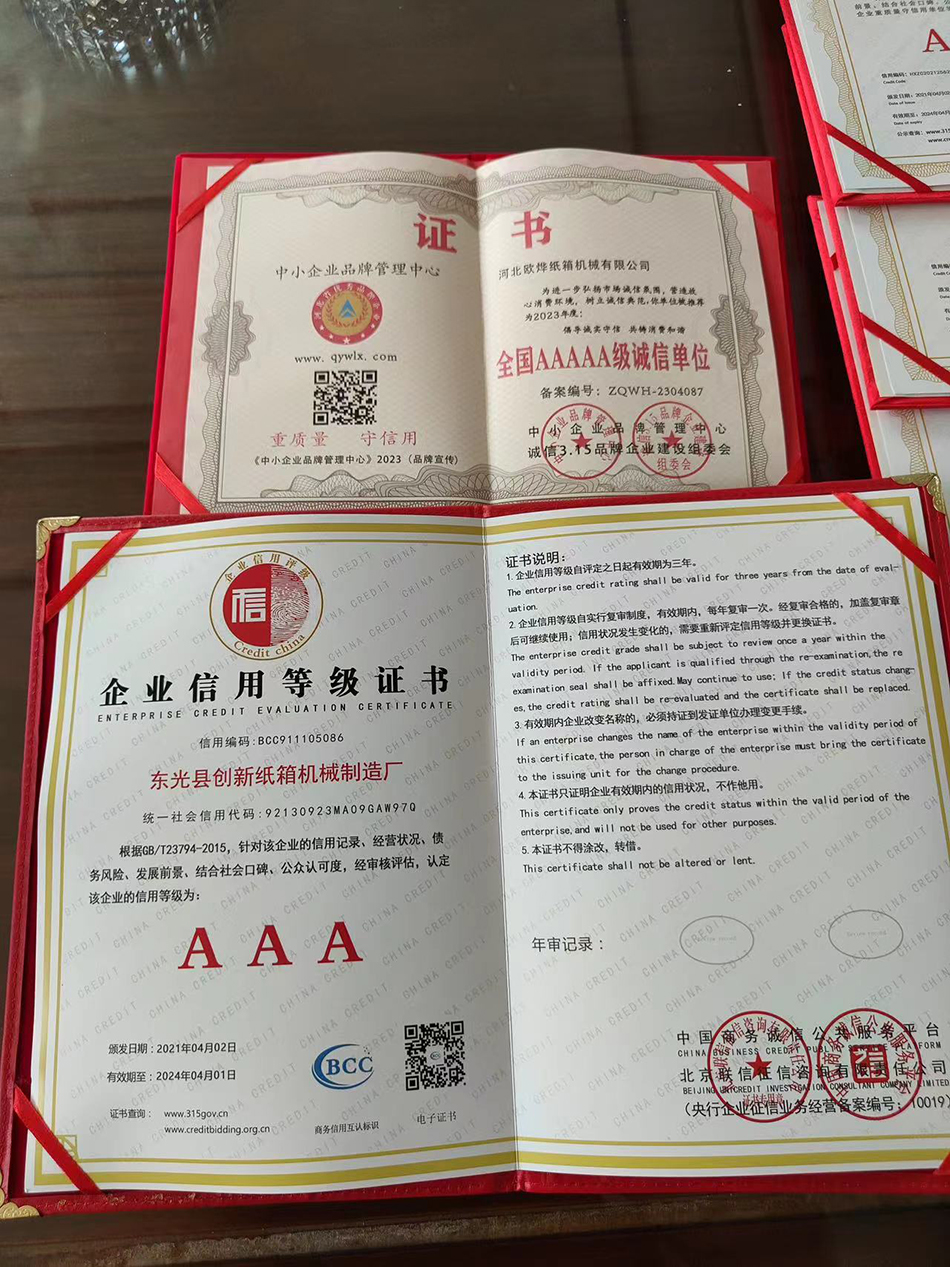

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory